Consulting & Prototyping

F2 Carbon - Fly Boatworks Prototype

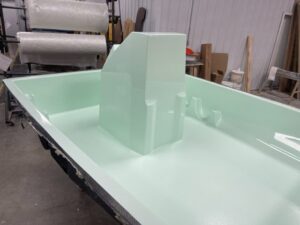

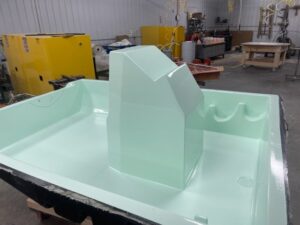

Master Composites, Inc. was contracted by Mark Fisher with Fly Boat Works, LLC in the winter of 2021 to help prototype an ultra-lightweight/high-strength poling skiff made for shallow water expeditions using today’s advanced materials to achieve maximum performance.

Master Composites, Inc. is known throughout Minnesota and the Midwest for its experience and knowledge in closed molding and advanced composites. Although we are not boat builders, we know everything about infusion. We were excited to work on such a fantastic project with Fly Boat Works, LLC!

Mark and his team – Sam Gilk & Dan Gilk, partnered with us to help infuse the hull, cap, liner, and all other components. This boat was made with a combination of today’s advanced materials, including Carbon, Basalt, and Inegra, resulting in one of the market’s highest-performing, lightest, and strongest skiffs.

To learn more or inquire about the F2 Carbon, visit Fly Boatworks’ website or find them on their Instagram.

Change Lane

Another Prototype one-off.

Master Composites worked with a team of design artists, welders, and engineers from a start-up company called Change Lane out of Minnetonka, MN. The concept was to produce a lightweight trailer as a mobile oil change station. With an aluminum frame and a completely lightweight composite exterior, the concept was no different than the average motor home or camper trailer, only that we had to utilize closed molding technologies to form the panels with the exterior skin of over 10,000 hemispheric bubbles! It is safe to say no details were left out on this project.

Washing Conveyor One-Off

Master Composites, Inc. was contracted in 2017 to produce a 100% composite conveyor. The entire concept was produced by hand. We utilized old-world craftsman skills to produce the scaled product within 1/16th inch tolerances.

The conveyor was unique because it required 100% chemical-resistant materials such as a chemical-rated surface veil, C glass, Isophthalic resin, and chemical-rated core materials. Even the hardware, bolts, and nuts were chemical-resistant FRP!